Guiding Elements

- Parts

- Parts (Inch)

- Parts (Metric)

- Kits

- Industrial Seal Kits

- Atlas

- Hydro-Line

- Miller Fluid Power

- Air Cylinders

- Hydraulic Cylinders

- Individual Parts

- STAR Bushings - Series A, J & H

- Bushings - Series A, J & H

- Retainers

- Rod Wipers

- Rod Seals - Air Service

- Rod Seals - Hydraulic Service

- Rod Seal Cage - Hydraulic Service

- Rod Seal Wave Spring - Hydraulic Service

- Bronze Pressure Ring - Hydraulic Service

- Piston Lipseals - Air Service

- Piston Lipseals - Hydraulic Service

- Piston Cups - Air Service

- Piston Cups - Hydraulic Service

- Piston Rings - Hydraulic Service

- Piston Wear Ring - Air Service

- Piston Wear Rings - Hydraulic Service

- Piston Follower Seals

- Parker

- Industrial Seal Kits

- Accessories

- Shaft Seals

Guiding Elements Select subcategory

Subcategories

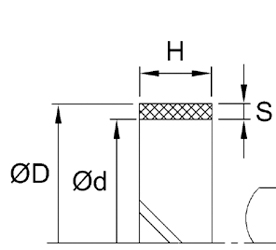

W1 W2 W3 W4 WR

GF.Nylon

-65/275F [-54/135C]

The W-Style wear-rings are primarily used on hydraulic/pneumatic cylinder pistons and rod glands. Their main function is to prevent metal-to-metal scoring as well as insuring that reciprocating parts are properly centered. Usually manufactured our of glass-filled Nylon, other popular materials are also available.WS

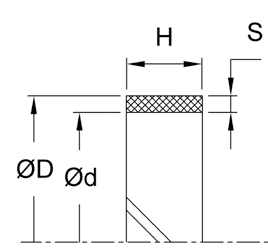

Wear Strip

Bronze PTFE/BR60

-400/550F [-240/287C]

Optional Material

Polyester Resin/PR

-40/250F [-40/121C]

The WS-style is made of fluorinated polymer and fortified bronze (other fillers available upon request). Designed to eliminate scoring in hydraulic and pneumatic applications by preventing metal to metal contact; WS-Wear strip is effectively used for reciprocating. rotary and oscillating motion. The tape form allows the product to be installed economically. whether for new installation or repair.“DU” Bearing

BR.PTFE/Steel

-328/536F [-200/280C]

44 000 PSI [3035 Bar]

* Compressive strengh

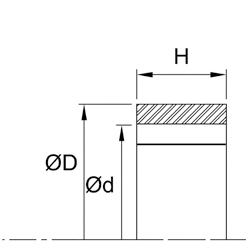

“DU” selflubricating bearings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions.

- Suitable for lubricated applications.

- Suitable for linear, oscillating and rotating movements.

SBB

Spherical Plain Bearings

Carbon Chromium Steel

(Without seals)

-58/302F [-50/150C]

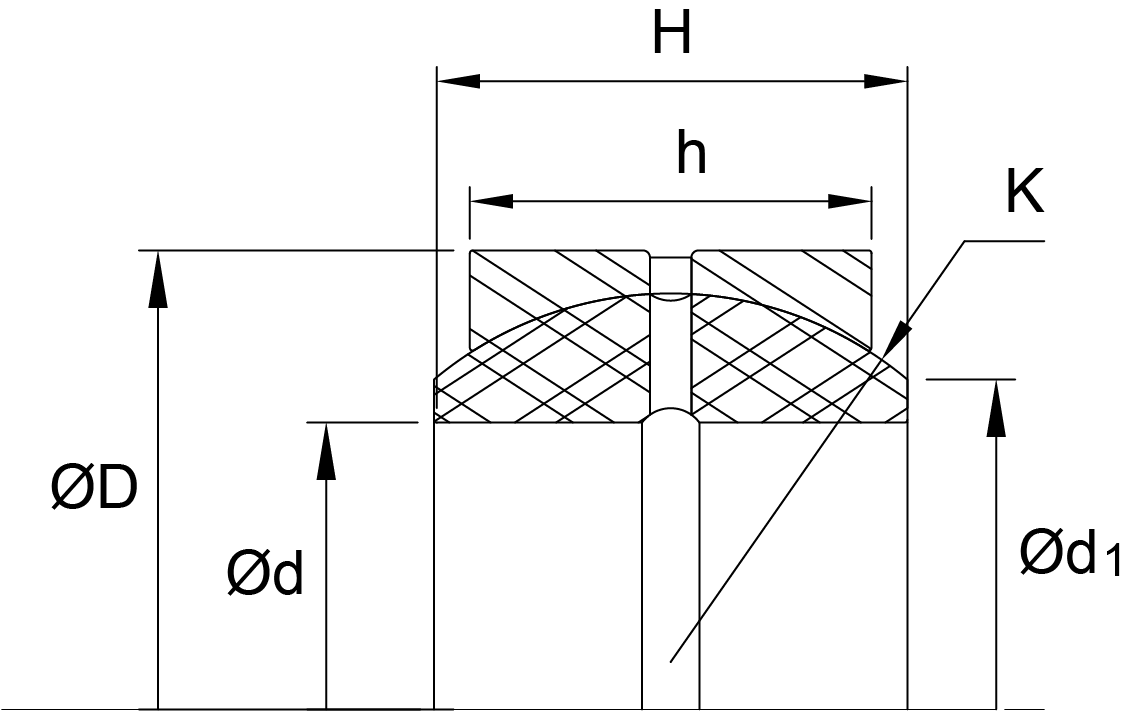

SBB-style Radial spherical plain bearings have an inner ring with a sphered convex outside surface and an outer ring with a correspondly sphered but concave inside surface. Their design makes them particulary suitable for bearing arrangements where alignment movements between shaft and housing have to be accomodated, or where oscillating or reccurent tilting or slewing movements must be permitted at relatively slow sliding speeds.SBB-2RS

Spherical plain bearings

Carbon Chromium Steel

(With seals)

-22/266F [-30/130C]

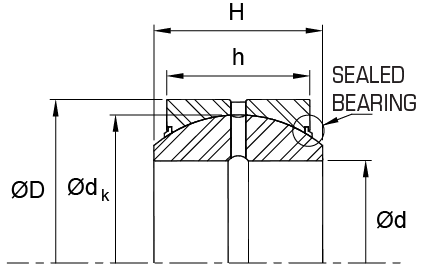

Similar to the SSB-style, the 2RS-style incorporates seals on the outer race to prevent the ingression of harmful contaminants.